Butterfly Valves

Butterfly valves are commonly found in pipeline applications where it’s necessary to isolate or regulate the flow of liquids, gases, and even some solid particles. Petroleum, oil and gas, water, wastewater, chemicals, power, HVAC, and pharmaceuticals are a few examples of these industries.

These kinds of butterfly valves, which enable a fast shut-off, are now frequently employed in place of ball valves. This is because Butterfly requires less room and support in the pipeline than larger-sized Ball styles, which can be more expensive, heavier, and more difficult to install.

What are the advantages of butterfly valves?

Butterfly valves are favoured for their compact and lightweight design, making them an efficient choice for systems where space is limited or weight considerations are important. Compared to other valve types, they are more cost-effective due to their simpler construction, which requires fewer materials and less complex manufacturing processes. This makes them a popular option in industries that require large-scale valve installations but also need to keep costs manageable. Additionally, their relatively small size makes installation and maintenance easier, further reducing overall operational expenses.

One of the key features of butterfly valves is their quick operation. Using a quarter-turn mechanism, they can be fully opened or closed with a simple 90-degree rotation of the disc, allowing for rapid control of flow. This quick action makes them highly efficient in situations where immediate flow regulation is needed. Butterfly valves are particularly suited for large-diameter pipes, as their design allows for the control of high volumes of fluid or gas without requiring significant force or energy. This makes them ideal for use in water treatment plants, HVAC systems, and other large-scale applications.

Can butterfly valves be used for throttling?

Butterfly valves can be used for throttling, or regulating flow, but their design makes them more suitable for low-pressure applications. While they offer the advantage of quick operation and can control flow efficiently, their disc remains in the flow path even when partially open, which can create turbulence and pressure drops. This makes them less ideal for high-pressure systems where precision control and minimal flow disruption are critical. However, in low-pressure environments, butterfly valves provide a cost-effective and efficient solution for throttling, balancing the need for flow regulation with simplicity and affordability.

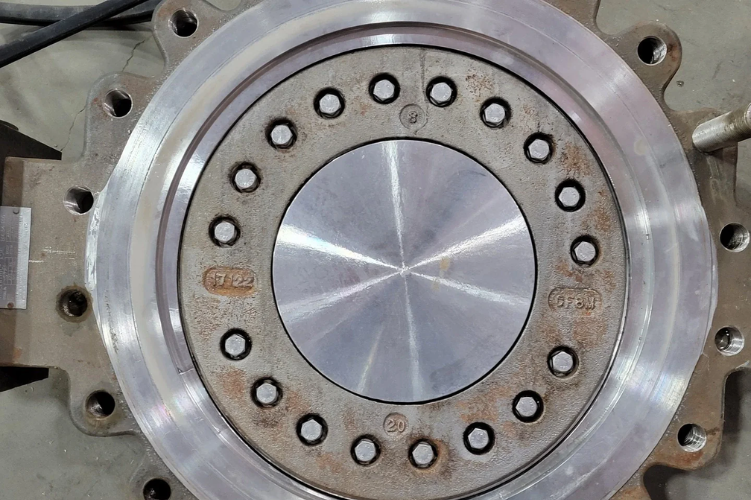

Lug Butterfly Valves

The lug butterfly valve eliminates the need for flanges by having lugs on the body of the valve, enabling direct installation to the pipe. The lug-style butterfly valve can be easily threaded with the counter flange bolts. Lug butterfly valves offer an inexpensive isolation method.

A lug-style valve can be a single, double, triple, or zero-offset butterfly valve; the most economical and widely used type is the zero-offset valve. Although the double and triple offset valves might have metal seats, these valves are usually resilient seated.

If your valve has a metal seat, find out if it can be replaced and what maintenance is required to keep the valve working for a long time.

Double Flange Butterfly Valves

With two flanges on the valve body, the double flange butterfly valve offers more security and stability in high-pressure situations.

A zero, single, double, or triple offset butterfly valve can be made with a flanged-style valve. The most popular and affordable offsets are the zero and single offsets.

Most flanged valves have durable seats. Non-replaceable seats make up the majority of robust seated valves in the flanged world. This implies that you will have to replace the entire valve if it starts to leak. More than anything else, the double flange describes the connection to the pipe. Applications requiring a tight seal, such chemical processing facilities or water treatment plants, are perfect for this kind of butterfly valve.

Want to learn more?

For a deeper insight into butterfly valves, including their design, functionality, and applications, please check out our comprehensive blog post. It offers detailed information that goes beyond the basics, helping you better understand these versatile valves. Click the link below to explore our in-depth article on butterfly valves!