Similar to the majority of mechanical components, most individuals are unaware of the existence of ball valves until they encounter an issue with them. However, ball valves operate silently and effectively in practically every tap that you use in daily life.

Ball valves are employed in numerous household appliances as well as in the food, medical, and manufacturing sectors. Many times, these valves can maintain the proper direction of flow for gases and liquids without the aid of complex technology.

This guide to ball valves will give comprehensive details about several types and their applications, including functions and mechanisms.

What is a ball valve?

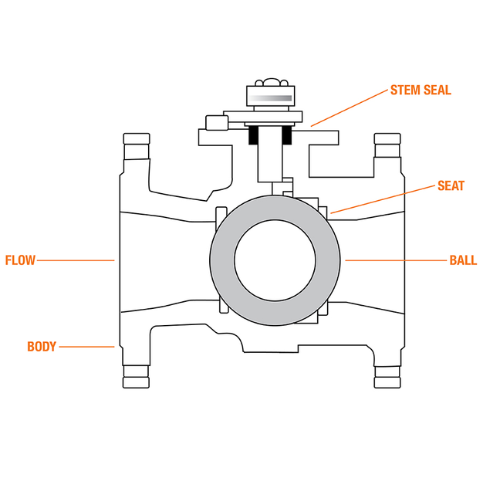

A ball valve is a type of shut-off valve. It is made up of a handle and a ball with a hole through the centre. Liquid or gas can pass through the hole by rotating the ball up to ninety degrees using the handle. The solid portion of the ball essentially forms a seal when the valve is closed, trapping anything in the pipe behind it.

Ball valves are durable and versatile, and they are available in a range of sizes and materials. Because of their straightforward design, getting them custom-fitted is simple. The primary constraint on a ball valve is the particular use for which it is intended. For low-pressure and low-temperature applications, a PVC ball valve might be perfectly adequate; however, to stop the flow of materials that are hot or under a lot of pressure, you might require a stainless steel ball valve.

Not every ball valve operates by hand. Certain valves, such as the electric ball valve, operate using an electrical current to rotate the ball and therefore open and close the valve. In high-pressure situations where the ball valve must open and close repeatedly, these motorised ball valves are employed.

How does a ball valve work?

A ball valve’s fundamental idea is straightforward. The valve is fitted with a ball that is the same size and shape as the pipe. This ball is propelled on its axis by a handle or gear, and a hole (often referred to in this context as a borehole) passes through its centre.

The solid portion of the ball closes the valve when it is in the closed position. When the valve is rotated, the pipe’s contents pass through it until it closes again. The entire borehole is exposed at a 90-degree rotation, enabling the contents of the pipe to flow freely. The ball valve handle can be partially rotated to control the flow.

Ball check valves operate similarly to conventional ball valves, with the exception that they typically feature a flap or disc to stop backflow. A ball valve of this kind stops flow as the pressure drops. The disc or flap is pushed aside when the pipe is opened by the pressure of the medium passing through it. To prevent the contents of the pipe from flowing backwards, the flap or disc falls back into place when the pressure moving forward weakens. Regardless of whether the ball valve is open or closed, this occurs.

What does a ball valve do?

A ball valve is a shut-off valve. It is employed to start and stop the passage of gases or liquids via a pipe or other restricted area. Almost every house or building with flowing water has a water ball valve employed in its systems.

Do ball valves control pressure?

Ball valves can be used to regulate the pressure in limited spaces such as pipelines. The ball valve can be partially opened to regulate the amount of pipe contents that pass through it. If you slightly open it, not much will flow and the pressure will be lower. The pressure and flow will both increase when the valve is fully opened.

Ball valves are used in traditional washbasin taps to regulate the water flow. You may control the amount of water that comes out of the tap by moving a ball valve by changing the taps.

PN: Pressure Nominal Classes

The PN Class number lets you know how much pressure the valve is designed to withstand. The PN is designated by bars, with each bar representing 14.5038 pounds of pressure. This means that a valve label with 3 bars would indicate that the underlying valve could withstand pressures of up to 43.5114 pounds.

PSI Rating

PSI stands for pounds per square inch and is a standard measurement for pressure in any circumstance. When listed on a valve tag or label, it indicates the pressure of the liquid or gas that is flowing through the pipe. The higher the PSI rating, the more durable the ball valve must be to withstand the force applied against it.

What does CWP mean on a ball valve?

CWP, an acronym for Cold Working Pressure, is a term commonly seen in the specifications of ball valves and other types of valves. It refers to the maximum pressure a ball valve can handle at room temperature (usually defined as 100°F or 38°C). Understanding the CWP is essential for ensuring the safety and efficiency of the ball valve in your system.

This means that you can count on a ball valve with a high CWP to perform well at the lower temperatures found in dairies, food processing plants, and anywhere else where cold media is travelling through the valve.

What does SWP mean on a ball valve?

SWP stands for steam working pressure. It may also be labelled WSP for working steam pressure. Either way, it means the same thing. It indicates the pressure the valve will continue to function at even in the highest temperature range.

Ball valves with a high SWP are essential for pipes that carry steam, lubricants for engines, and hydraulic systems where friction may heat the oil. They have many industrial uses.

The 10 Most Important Types of Ball Valves

Ball valves are incredibly efficient, long-lasting, and easy to replace or repair. We utilise them in practically every home, business, and production facility as a result of these benefits. Ball valves are used everywhere there are pipes to regulate the medium flow within them.

1. Sanitary Ball Valve

These valves are intended for use in the production of pharmaceuticals, the food sector, and any other setting where sterilisation is necessary. These can be manually, mechanically, or electrically operated ball valves, and they are available in a wide range of sizes and designs. They all feature polished, smooth surfaces that keep debris from building up and maybe sterilised using heat or chemicals.

2. V-Port Ball Valves

The V-port ball valve, in contrast to conventional ball valves, has a floating ball that is compressed when the valve is open instead of a ball with a borehole. The ball enlarges and blocks the valve’s in and out ports when the valve is closed. This feature produces a tighter seal.

3. Full Port Ball Valve

The diameter of the borehole in a full port ball valve matches that of the pipe that leads to the valve. This kind of ball valve, when fully opened, permits the contents of the pipe to flow freely without clogging the valves. These valves are typically seen in applications where high-pressure ball valves are being used or where the medium in the pipes has to flow continuously.

4. Multi-Port Ball Valve

These valves can be 3-way ball valves or have additional connectors that enable the medium’s flow to be redirected as needed. They can be built such that more than one connector can be opened at once, or they can be made so that the flow only moves in one direction at a time.

5. Standard Port Ball Valve

Standard port ball valves feature boreholes that are smaller in diameter than the pipes that enter them. Even when fully opened, they still limit the flow of the pipe’s contents, but they are typically more affordable and robust than full-bore ball valves.

6. Reduced Port Ball Valve

Reduced port ball valve is another name for the standard port ball valve, which is explained in number 5.

7. True Union Ball Valve

The pipelines that house these ball valves have double unions. The unions can be fully removed for maintenance or replacement because they can be sealed at either end of the valve.

8. Manually Operated Ball Valve

Many different configurations of ball valves may fall into this category. As the name implies, you manually control these valves using a handle mounted outside of the pipe.

9. Electric Ball Valves

Electric ball valves are opened and closed by an electrical current instead of a handle.

10. Motorised Ball Valves

These valves are electric ball valves. They use an electrically powered motor mounted over the valve that opens and closes it as needed. Motorised ball valves are commonly found in automated factories and manufacturing plants.

Conclusion

In conclusion, ball valves are versatile and essential components in a wide range of applications, offering reliability, durability, and ease of use. Understanding their types, materials, and operational features can significantly enhance their performance in various systems, whether for industrial, residential, or commercial use.

By selecting the right ball valve for specific needs and maintaining them properly, you can ensure long-term functionality and efficiency. Whether you’re an engineer, a technician, or a DIY enthusiast, this guide provides the foundation to make informed decisions when working with ball valves.