What is a Gate Valve?

Pipelines above and below ground frequently use gate valves, which are a kind of linear valve. With a gate valve, users can isolate a specific portion of the pipe as needed. It is meant to start and stop the flow of liquid through ducting. They are frequently referred to as sluice valves or water gate valves.

When someone asks what a gate valve is, they frequently follow up with queries for more details. What are the different kinds of gate valves, what elements they do they involve, how they differ from one another, and how exactly do they operate. In the many sections of this guide, we will go over each of these topics.

The valve body of a gate valve is often put in-line (through-conduit) on a pipe length, and it is operated by a handwheel actuator that is attached. Most frequently, this multi-turn wheel assembly extends above or to the side of the pipe and valve and is connected by a stem to a bonnet assembly. To open the valve, turn it in one direction; to close it, turn it in the other.

A gate valve’s benefit is that it may completely stop all water flow. This is very useful for maintenance, pipe cleaning, and troubleshooting. In addition, they don’t significantly reduce pressure when in use and are bidirectional, so they can be used to stop flow both upstream and downstream.

One of the limitations of gate valves in some situations could be their slow opening and closing speeds. Also, they are not made to be partially opened or closed to throttle or control flow.

What are Gate Valves Used for?

Sluice valves or water supply control valves are the most common names for the majority of gate valve types. Gate valves allow a pipeline segment to be fully closed off and isolated as needed. This is done by allowing the flow of liquid (or steam/gas) to be started or stopped in that segment.

These are among the most widely utilised types of taps and valves in pipeline applications. They are employed in many different industrial contexts. Usually, these could consist of:

- Oil and gas extraction

- Processing plants and water treatment facilities

- Various types of factories and production environments

- Medical and laboratory uses

- Food production and catering

- Automotive and mechanical

- Marine and offshore uses

There are gate valve types that are frequently good options for applications involving high pressure and/or high temperature. In theory, they are a rather simple kind of valve, but when applied properly, they may be very effective. They are a good option in situations with high pressure and temperature because they are fire-safe.

In contrast to globe valves and other shutdown valve types, gate valves are designed to be utilised exclusively in one of two states. Either fully open or fully closed. Leaving it partially raised or lowered will not control the medium flow rate in the pipe very much, and you run the danger of excessive vibration damaging or relocating the valve.

How Does a Gate Valve Work?

Gate valves function by physically blocking the pipeline with a gate or disc that closes to seal it off when closed and lifts it out of the way when opened. A handwheel on the valve bonnet, which acts as the valve actuator, raises and lowers this barrier. To begin or stop the liquid flow as needed, it rotates in both clockwise and anticlockwise directions.

To put it briefly, a gate valve is a kind of isolation or shutdown valve that is operated by a handwheel. There are two possible ways to link the handwheel actuation system: rising-stem and non-rising-stem designs. Because of their efficiency and simplicity of use, gate valves made of brass, stainless steel, and iron bodies are frequently utilised in a variety of pipeline and plumbing applications. In addition, depending on the size, type, and brand, they are typically reasonably priced to purchase, dependable, and mechanically fairly simple.

Distinguishing Gate Valves

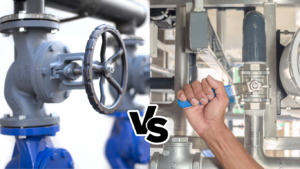

A ball valve, which differs slightly from a gate valve in terms of its physical design, is another popular kind of isolation valve. Nevertheless, both will have the same outcome when fully closed. This that that they will stop the flow of water via a duct. When choosing between a gate valve and a ball valve for a particular pipeline application or industrial setting, there are several important considerations to make. These usually include the types of environments in which they are employed. This will be as well as the characteristics of the medium in which the flow is being controlled.

It’s important to distinguish between gate valves and butterfly and check valves. These are two additional common pipeline devices that regulate directional flow. Check valves and gate valves vary primarily in that the former is made to stop backflow; that is, they permit flow in one direction while obstructing it in the other. On the other hand, when gate valves are closed, they stop the passage of gas, liquid, or vapour in both directions.

An alternative to a gate or isolation valve is a butterfly valve. Typically, all it takes to open or close them is a quarter turn of the valve actuator handle. Depending on where the actuation device is about the valve body, the gate itself sits either parallel or perpendicular to the flow direction inside the pipe. Though certain types can be throttled, they are typically less appropriate than gate valves in scenarios where obtaining a very tight seal is essential.

Gate valves come in two primary varieties: wedge-shaped and parallel. Two inclined seats and an inclined gate or barrier that is purposefully slightly out of alignment with the seats are used in wedge-shaped gate valves, which include solid taper wedges, flexible wedges, and split wedge designs. In some applications, this usually results in a tighter seal than a parallel version. A flat gate or barrier is held perpendicular to the liquid flow between two parallel seats in a parallel gate valve, also known as a parallel disc, double disc, or parallel sliding gate valve.

Gate Valve Diagram

This is a cut-out diagram showing typical parts of a gate valve, giving you a visual indication of its basic components, stem design and function.

Key parts such as the bonnet, stem, handwheel, and valve body are labelled for clearer identification.

Gate Valve Types

Different types of gate valves are employed in many different pipeline and workplace applications. Here is a list of some of the most widely used gate valve varieties available for purchase in the UK and other countries, along with a brief description of each sort.

Wedge Gate Valves

Among the more popular varieties, wedge gate valves are utilised extensively in all pertinent industrial and plumbing pipeline configurations. The split wedge, flexible wedge, and solid wedge are examples of subtypes.

Plain wedge valves, also known as solid wedge gate valves, are typically the most used. They have considerable mechanical strength yet are frequently among the easiest and least expensive solutions. They can be used with almost any kind of fluid media. Their sturdy, one-piece design makes them particularly suitable for use in turbulent fluid flow pipelines.

The barrier or gate of a wedge valve is angled slightly away from the pressurised liquid’s flow route in the pipe. They are also known as tapered gates as a result. This angle creates a wedging force as the valve closes, and helps to make for a more reliable seal at higher fluid pressure ratings.

Split Gate Valves

The wedge disc of a split gate valve, also known as a split wedge gate valve, is composed of two solid sections that are secured together by a spacer or spring. It can self-adjust to the seats. This gives it more flexibility and facilitates the creation of a tighter seal with a lower chance of sticking or binding. They work especially well with corrosive liquids and non-condensing gases.

Parallel Gate Valves

Similar in function to a wedge gate valve, a parallel gate valve has two discs positioned at a 90-degree angle to the direction of fluid flow. This type of gate is also known as a parallel disc gate valve or parallel slide gate valve. In high-temperature applications, where the parallel design is less prone to cause thermal binding, they are typically regarded as safer.

Knife Gate Valves

One popular type of gate valve is the knife gate valve. These valves are mainly intended for usage with particularly viscous or thick fluids, like slurry or liquid used to convey powder. To make it easier for the discs in the knife gate valve model to cut and pass through thicker media while closing, one end of the discs is tapered or sharpened, hence the name knife valves.

Flanged Gate Valves

A gate valve with a flanged body is one whose bonnet (the portion on top of the valve that links the handwheel assembly and provides access to the working parts of the valve) is attached to the valve body. As a result, they are often less suitable than specialised pressure sealing types, but more appropriate for applications involving higher pressures than bolted connections.

How to Use a Gate Valve

The user merely needs to move the handwheel in the appropriate direction to open or close the gate valve as needed to operate it. A gate valve is opened or closed by turning the wheel 360 degrees in the desired direction. This raises or lowers the attached gate disc by turning the threaded valve stem.

How to Tell If a Gate Valve is Open or Closed

It is not always simple to determine whether a gate valve is open or closed. Especially in contrast to several other types of flow valves. For instance, when the handle of a ball or butterfly valve is orientated perpendicular to the pipeline or flow direction, the valve will typically close.

You can’t always identify which position gate valve wheels are in at a look because they revolve 360 degrees to open and close and sit above or to the side of the pipe. A gate valve typically opens when turned anticlockwise and closes when turned clockwise. Usually, the handwheel or another area of the valve’s outside body will bear markings indicating these directions.

You should always cease operating gate valves when you notice noticeable resistance. This is only if you are positive that the valve is jammed or bound. A gate valve, along with the piping or ducting it is installed on, may sustain harm if it is turned against resistance indefinitely. Therefore, to find out which position a gate valve is in at any one time, it could be required to try twisting it in either direction.