Butterfly valves are staples in various industries, and are known for their versatility and efficient flow control capabilities. With different designs and configurations available, choosing the right type of butterfly valve can significantly impact the performance and reliability of a system. In this guide, we’ll explore the various types of butterfly valves, focusing on the differences between eccentric and concentric designs and shedding light on lug and semi-lug variations.

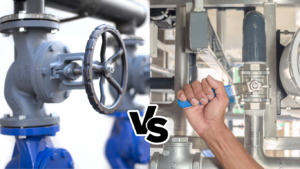

Eccentric vs Concentric Butterfly Valves

Eccentric Butterfly Valves: In eccentric butterfly valves, the stem is positioned slightly off-centre from the disc’s centerline. This design allows the disc to completely disengage from the seat during operation, minimising wear and reducing torque requirements. Eccentric butterfly valves are ideal for applications requiring high performance and tight shut-off capabilities.

Concentric Butterfly Valves: Concentric butterfly valves feature a stem aligned with the centerline of the disc. While simpler in design compared to eccentric valves, they offer reliable performance and are suitable for a wide range of applications. Concentric butterfly valves are often more cost-effective and easier to install, making them popular choices for general-purpose use.

Lug and Semi-Lug Butterfly Valves

Lug Butterfly Valves: Lug butterfly valves are equipped with threaded inserts, or lugs, on the valve body. These lugs allow for easy installation and removal of the valve from the pipeline using bolts without affecting the integrity of the system. Lug valves are typically used in applications where the valve needs to be installed between two flanges or in systems that require frequent maintenance.

Semi-Lug Butterfly Valves: Semi-lug butterfly valves feature lugs on only one side of the valve body, while the other side is flanged. This design provides the convenience of easy installation and removal on one end while allowing for direct connection to the pipeline on the other end. Semi-lug valves offer versatility and are suitable for a wide range of applications, particularly where space constraints or accessibility issues are a concern.

Considerations for Selection

When choosing a butterfly valve, several factors should be taken into account to ensure optimal performance:

– Operating Conditions: Consider factors such as pressure, temperature, and media compatibility to select a valve that can withstand the intended conditions.

– Flow Characteristics: Evaluate the flow requirements of the system and choose a valve with appropriate flow control capabilities.

– Installation and Maintenance: Determine whether a lug or semi-lug design is preferable based on accessibility and maintenance considerations.

– Cost and Lifecycle: Balance initial investment with long-term durability and reliability to achieve the best value for your application.

Conclusion

Butterfly valves offer a versatile and efficient solution for flow control in various industries. Understanding the differences between eccentric and concentric designs, as well as the variations in lug and semi-lug configurations, is essential for selecting the right valve for your specific requirements.

By considering factors such as operating conditions, flow characteristics, and installation/maintenance needs, engineers and operators can make informed decisions to ensure optimal performance and reliability in their systems. With the right butterfly valve in place, you can achieve efficient flow control and enhance the overall productivity of your processes.