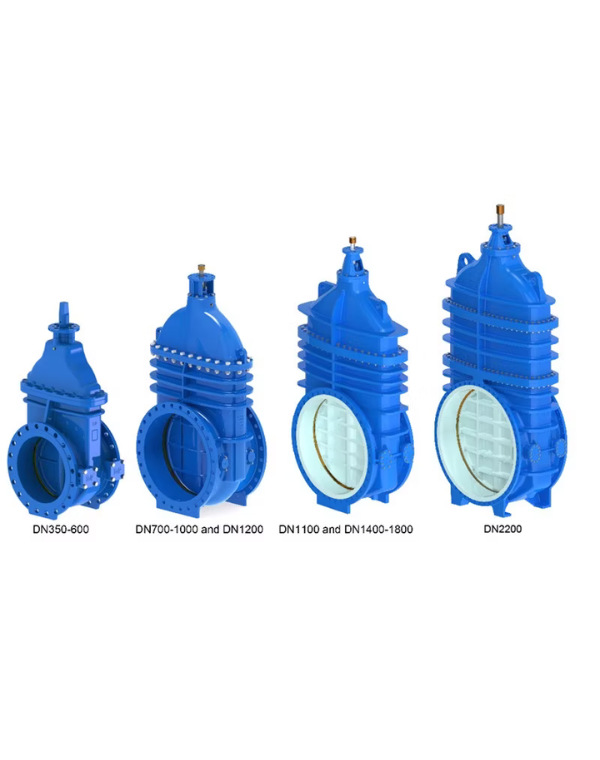

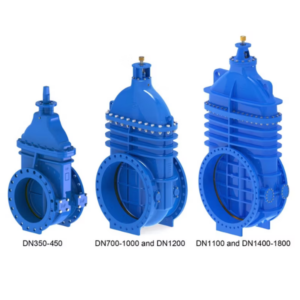

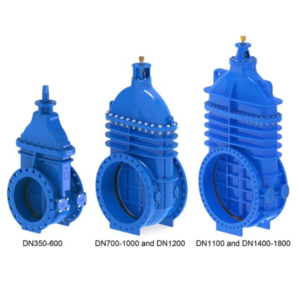

AVK METAL SEAT GATE VALVE, FLANGED, PN 10/16 DN350-1800

SS stem, alu-bronze seat, S&C, A4/galv. 8.8 bolts, CTC/CTO, blue FBE/2-pack

Metal seat gate valves with rotating, non-rising stem. Operating direction clockwise to close or clockwise to open. For drinking water and neutral liquids to max. 70°C. On DN300-600 operation is either by manual handwheel/gearbox or by electric actuation; on DN≥700 operation is possible only via gearbox or actuator that is able to support the axial thrust loads.

Description

Key Features

- High strength alu-bronze valve seat

- Metal faces machined to a high finish for optimum contact and minimum leakage

- Stem in stainless steel

- DN350-600 four separate and independent O-ring stem seals

- DN≥700 stuffing box with ample depth gives long life to the PTFE packing

- Round body-bonnet O-cord gasket fixed in a recess to avoid blow-out

- Full bore

- Lifting eyes for easy handling

- All rubber and coating in contact with the water are drinking water approved

- Copper alloy shoes and channels provide low friction guides for the wedge when opening and closing

- DN350-600 protected fasteners in galvanized 8.8 steel, exposed fasteners in A4 stainless steel

- DN≥700 fasteners in galvanized 8.8 steel

- DN 350-1000 protected by 250µm blue fusion bonded epoxy coating

- DN≥1100 protected by 250µm blue 2-pack epoxy coating

- Prepared for by-pass

Information

AVK Series 54 gate valves are designed with built-in safety and quality in every detail. The metal valve seat is resistant to high temperatures in the medium and will not deform during long periods of compression. This ensures stable and reliable operation over the long life span of the valve.

| Variant 54/3132-002 | |

|---|---|

| Connection: | Flanged |

| Material: | Ductile Iron |

| DN: | DN350 – DN1000 |

| PN: | PN 16 |

| 1. | Body | Ductile Iron GJS-500-7 |

| 2. | Seat ring | Alu-bronze CC331G (AB1) |

| 3. | Face ring | Alu-bronze CC331G (AB1) |

| 4. | Wedge | Ductile Iron GJS-500-7 |

| 5. | Wedge nut | Alu-bronze CC333G (AB2) |

| 6. | Stem | Stainless steel 1.4057 (431) |

| 7. | O-cord | EPDM |

| 8. | Bonnet | Ductile Iron GJS-500-7 |

| 9. | Air plug | Stainless steel |

| 10. | Key | Steel |

| 11. | Channel | Copper alloy |

| 12. | Shoe | Copper alloy |

| 13. | Bolts | Hot dip galvanized steel |

| 14. | Blanking plate | Ductile Iron GJS-500-7 |

| 15. | O-ring | EPDM |

| 16. | Stem Cap | Ductile Iron GJS-500-7 |

| 17. | Seal | Hot melt glue |

| 18. | Gland flange | Ductile Iron GJS-500-7 |

| 19. | Thrust collar | Alu-bronze CC331G (AB1) |

| 20. | Gland flange bolt | Hot dip galvanized steel |

| 21. | Seal | Hot melt glue |

| 22. | Bonnet bolt | Hot dip galvanized steel |

| 23. | Thrust nut | Alu-bronze CW307G |

| 24. | Distance piece | Ductile Iron GJS-500-7 |

| 25. | Gland | Ductile Iron GJS-500-7 |

| 26. | Packing | PTFE |

| 27. | Stuffing box | Ductile Iron GJS-500-7 |

| 28. | Upper part | Ductile Iron GJS-500-7 |

Standards

- Designed according to BS EN 1074 -1 and 2

- WIMES 8.09 Compliant

- Drinking Water Inspectorate Regulation 31 compliant

Test/Approvals

- Hydraulic test according to EN 1074-1 / EN 12266

Additional information

| Reference No. | 54-0350-31-1101101, 54-0350-32-1101101, 54-0400-31-1101101, 54-0450-31-1101101, 54-0450-32-1101101, 54-0600-31-1101101, 54-0700-31-0101101, 54-0700-31-1101101, 54-0700-32-0101101, 54-0700-32-1101101, 54-0800-31-0101101, 54-0800-31-1101101, 54-0800-31-1102101, 54-0800-32-0101101, 54-0800-32-1101101, 54-0900-31-0102101, 54-0900-31-1102101, 54-0900-32-0102101, 54-0900-32-1102101, 54-1000-31-0102101, 54-1000-32-0102101, 54-1000-32-1102101, 54-1000-32-1342100 |

|---|---|

| Brand | AVK |

| PN | PN10, PN16 |

Reference Nos. and Dimensions

| Ref. no. | DN

mm |

Operating

Direction |

Flange

Drilling |

L

mm |

H1

mm |

H2

mm |

W

mm |

W1

mm |

F

mm |

F1

mm |

F2

mm |

ISO

Flange |

Theoretical

Weight (kg) |

| 54-0350-31-1101101 | 350 | CTC | PN16 | 381 | 789 | 280 | 605 | 325 | 40 | 48 | 162 | 14 | 256 |

| 54-0350-32-1101101 | 350 | CTO | PN16 | 381 | 789 | 280 | 605 | 325 | 40 | 48 | 162 | 14 | 256 |

| 54-0400-31-1101101 | 400 | CTC | PN16 | 406 | 880 | 310 | 657 | 355 | 40 | 48 | 162 | 14 | 290 |

| 54-0450-31-1101101 | 450 | CTC | PN16 | 432 | 961 | 340 | 720 | 385 | 40 | 48 | 162 | 14 | 409 |

| 54-0450-32-1101101 | 450 | CTO | PN16 | 432 | 961 | 340 | 720 | 385 | 40 | 48 | 162 | 14 | 409 |

| 54-0600-31-1101101 | 600 | CTC | PN16 | 508 | 1202 | 440 | 905 | 485 | 40 | 48 | 162 | 14 | 636 |

| 54-0700-31-0101101 | 700 | CTC | PN10 | 610 | 1497 | 450 | 1050 | 421 | – | – | 116 | 14 | 1429 |

| 54-0700-31-1101101 | 700 | CTC | PN16 | 610 | 1497 | 450 | 1050 | 421 | – | – | 116 | 14 | 1429 |

| 54-0700-32-0101101 | 700 | CTO | PN10 | 610 | 1497 | 450 | 1050 | 421 | – | – | 116 | 14 | 1429 |

| 54-0700-32-1101101 | 700 | CTO | PN16 | 610 | 1497 | 450 | 1050 | 421 | – | – | 116 | 14 | 1429 |

| 54-0800-31-0101101 | 800 | CTC | PN10 | 660 | 1689 | 535 | 1160 | 495 | – | – | 116 | 14 | 1779 |

| 54-0800-31-1101101 | 800 | CTC | PN16 | 660 | 1689 | 535 | 1160 | 495 | – | – | 116 | 14 | 1779 |

| 54-0800-31-1102101 | 800 | CTC | PN16 | 660 | 1689 | 535 | 1160 | 495 | – | – | 129 | 16 | 1779 |

| 54-0800-32-0101101 | 800 | CTO | PN10 | 660 | 1689 | 535 | 1160 | 495 | – | – | 116 | 14 | 1779 |

| 54-0800-32-1101101 | 800 | CTO | PN16 | 660 | 1689 | 535 | 1160 | 495 | – | – | 116 | 14 | 1779 |

| 54-0900-31-0102101 | 900 | CTC | PN10 | 711 | 1844 | 596 | 1310 | 535 | – | – | 131 | 16 | 2330 |

| 54-0900-31-1102101 | 900 | CTC | PN16 | 711 | 1844 | 596 | 1310 | 535 | – | – | 131 | 16 | 2330 |

| 54-0900-32-0102101 | 900 | CTO | PN10 | 711 | 1844 | 596 | 1310 | 535 | – | – | 131 | 16 | 2330 |

| 54-0900-32-1102101 | 900 | CTO | PN16 | 711 | 1844 | 596 | 1310 | 535 | – | – | 131 | 16 | 2330 |

| 54-1000-31-0102101 | 1000 | CTC | PN10 | 813 | 2007 | 648 | 1404 | 602 | – | – | 136 | 16 | 3072 |

| 54-1000-32-0102101 | 1000 | CTO | PN10 | 813 | 2007 | 648 | 1404 | 602 | – | – | 136 | 16 | 3072 |

| 54-1000-32-1102101 | 1000 | CTO | PN16 | 813 | 2007 | 648 | 1404 | 602 | – | – | 136 | 16 | 3072 |

| 54-1000-32-1342100 | 1000 | CTO | PN16 | 3070 |

Reviews

There are no reviews yet.