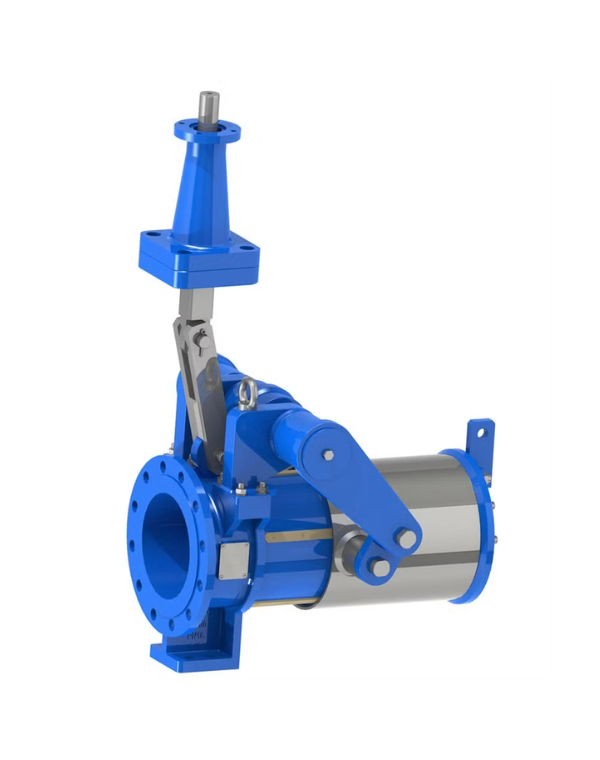

SUBMERGED DISCHARGE VALVE, PN 25

Bare shaft DN800 – 1000

Submerged discharge valve for dam and reservoir fresh water.

Available on back-order

Description

Key Features

-

Terminal discharge valves situated at the end of the pipeline and are installed in a compact stilling sump

-

Stilling sump providing submerged discharge with safe and quiet energy dissipation

- Hydraulic balance, no differential loads, low operating effort, small actuator

- Resilient seal for drop-tight shut off

- Submerged discharge, safe, quiet energy dissipation and cavitation free

- Chloride resistant stainless steel internal parts, bronze ported body with epoxy coated ductile iron components for high corrosion resistance

-

Shaped multi-ports giving wide control range, can be customized for specified condition

-

External mechanism allowing easy maintenance and visible indication

-

Fine screw thread for slow speed operation and fine adjustment, good positioning and gradual flow change

The AVK submerged discharge valves are designed to safely dissipate the surplus energy from large amounts of rapidly flowing water. Installed at the outlet of dams or reservoirs and discharging sub-surface into a stilling basin, they operate with a minimum of noise and a maximum of safety.

| Variant 856/2-001 | |

|---|---|

| Connection: | Flanged |

| Material: | Ductile Iron |

| PN: | PN 16 |

| 1. | Stopper pipe | Ductile Iron GJS-500-7 |

| 2. | Bottom valve spindle | Stainless steel 1.4057 |

| 3. | Guide spider | Ductile Iron GJS-500-7 |

| 4. | Bush | Alu-bronze CW307G |

| 5. | Screw | Stainless steel A4-70 |

| 6. | Extension pipe | Ductile Iron GJS-500-7 |

| 7. | Bolt | Stainless steel A4-70 |

| 8. | Intermediate spindle | Stainless steel 1.4057 |

| 9. | Upper valve spindle | Stainless steel 1.4057 |

| 10. | Taper pipe | Ductile Iron GJS-500-7 |

| 11. | Inlet bend | Ductile Iron GJS-500-7 |

| 12. | Coupling | Ductile Iron GJS-500-7 |

| 13. | Ductile Iron GJS-500-7 | |

| 14. | Upper pillar | Ductile Iron GJS-500-7 |

| 15. | Spindle | Stainless steel 1.4057 |

| 16. | Eye bolt | Hot dip galvanized steel |

| 17. | Foundation bolt | Stainless steel 1.4401 |

| 18. | Spring Washer | Stainless steel A4-70 |

| 19. | Plug | Bronze |

| 20. | Baseplate | Ductile Iron GJS-500-7 |

| 21. | Ported body | Alu-bronze CC333G |

| 22. | Baseplate | Stainless steel 1.4057 |

| 23. | Sleeve | Stainless steel 1.4401 |

| 24. | Washer | Stainless steel A4-70 |

| 25. | Upper valve body | Ductile Iron GJS-500-7 |

| 26. | Lifting nut | Stainless steel 1.4057 |

| 27. | Gasket | EPDM |

| 28. | Handhole cover | Ductile Iron GJS-500-7 |

| 29. | Face ring | Neoprene |

| 30. | Guide ring | Bronze |

| 31. | Seal ring | Neoprene |

| 32. | O-ring | EPDM |

| 33. | Gland ring | Bronze |

| 34. | Guide spider | Ductile Iron GJS-500-7 |

| 35. | O-ring | EPDM |

| 36. | Gasket | EPDM |

| 37. | Packing | PTFE |

| 38. | Stuffing box | Ductile Iron GJS-500-7 |

| 39. | Gland | Ductile Iron GJS-500-7 |

| 40. | Washer | Stainless steel 1.4401 |

| 41. | Hex Nut | Stainless steel A4-70 |

| 42. | Key | Stainless steel A4-70 |

| 43. | Torque plate | Stainless steel 1.4401 |

Test/Approvals

- Seat: 1.1 x PN (in Bar), Body: 1.5 x PN (in Bar). Closing torque test.

Standards

- Standard flange drilling to EN1092 (ISO 7005-2), PN 25

Additional information

| Variant | 856/2-001 |

|---|---|

| Brand | AVK |

| Connection | Flanged |

| PN | PN16 |

Reviews

There are no reviews yet.