In the complex network of industrial piping and valves, where precision and efficiency are crucial, fittings stand as a key aspect. These small components play a pivotal role in ensuring seamless fluid flow, structural integrity, and safety within industrial systems. Let’s delve into the realm of fittings, exploring their significance, types, and applications in the industrial landscape.

What are Fittings?

Fittings act as connectors, bridging various sections of piping and valves to create a cohesive system for fluid transport. Their primary function is to join pipes of different diameters, shapes, or materials, facilitating the directional flow of liquids, gases, or even solids within industrial setups. Beyond mere connection, fittings also accommodate changes in direction, branch off pipelines, regulate flow, and enable maintenance tasks like inspection and cleaning.

Types of Fittings

1. Couplings: These are the simplest form of fittings, used to connect two pipes end-to-end. Couplings come in various designs such as compression fittings, threaded couplings, and clamp fittings, offering versatility in different applications.

2. Elbows: When pipes need to change direction, elbows are used. They are available in different angles like 45°, 90°, and 180°, allowing flexibility in routing pipelines around obstacles or corners.

3. Tees: Tees resemble the letter “T” and are employed when a pipeline needs to branch off in two directions. They ensure equal flow distribution and are crucial in designing complex piping systems.

4. Y-shaped Tee: An industrial pipe fitting designed to split or combine fluid flow within a piping system. They feature a main inlet and two outlets at a 45-degree angle for minimal turbulence and pressure drop. Its design offers efficient flow management and space-saving versatility in complex piping networks.

5. Reducers: As the name suggests, reducers facilitate the transition between pipes of different diameters. They ensure a smooth flow without causing pressure drops or turbulence.

6. Unions: Unions are detachable fittings comprising threaded or flanged connections, allowing easy disassembly of pipelines for maintenance or repairs.

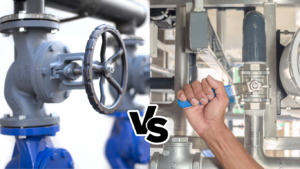

7. Valves and Flanges: While valves regulate fluid flow, flanges provide a method for joining pipes securely. This is often with bolts or welding.

Applications Across Industries

The importance of fittings transcends various industrial sectors, including:

– Oil and Gas: From offshore rigs to refineries, fittings play a crucial role in transporting petroleum products, natural gas, and other fluids safely and efficiently.

– Chemical Processing: In chemical plants, where corrosive substances are handled, fittings must be resistant to chemical degradation to maintain operational integrity.

– Water Treatment: Fittings are integral to water treatment facilities. They ensure the smooth flow of potable water or wastewater for purification and distribution.

– Manufacturing: In manufacturing facilities, fittings facilitate the movement of raw materials, cooling fluids, and hydraulic oils to power machinery and equipment.

– HVAC Systems: Heating, ventilation, and air conditioning systems rely on fittings for ductwork, ensuring optimal airflow and climate control within buildings.

Conclusion

Fittings may appear as a minuscule aspect when compared to the sprawling pipelines and imposing valves in industrial settings, but their significance cannot be overstated. They are the linchpin that holds the entire system together, enabling seamless fluid transport and system functionality.

As industries continue to evolve and demand higher standards of efficiency and safety, the role of fittings remains indispensable, driving innovation and advancements in fluid control technology. In the intricate dance of industrial piping and valves, fittings are the silent choreographers, orchestrating the flow of fluids with precision and reliability.