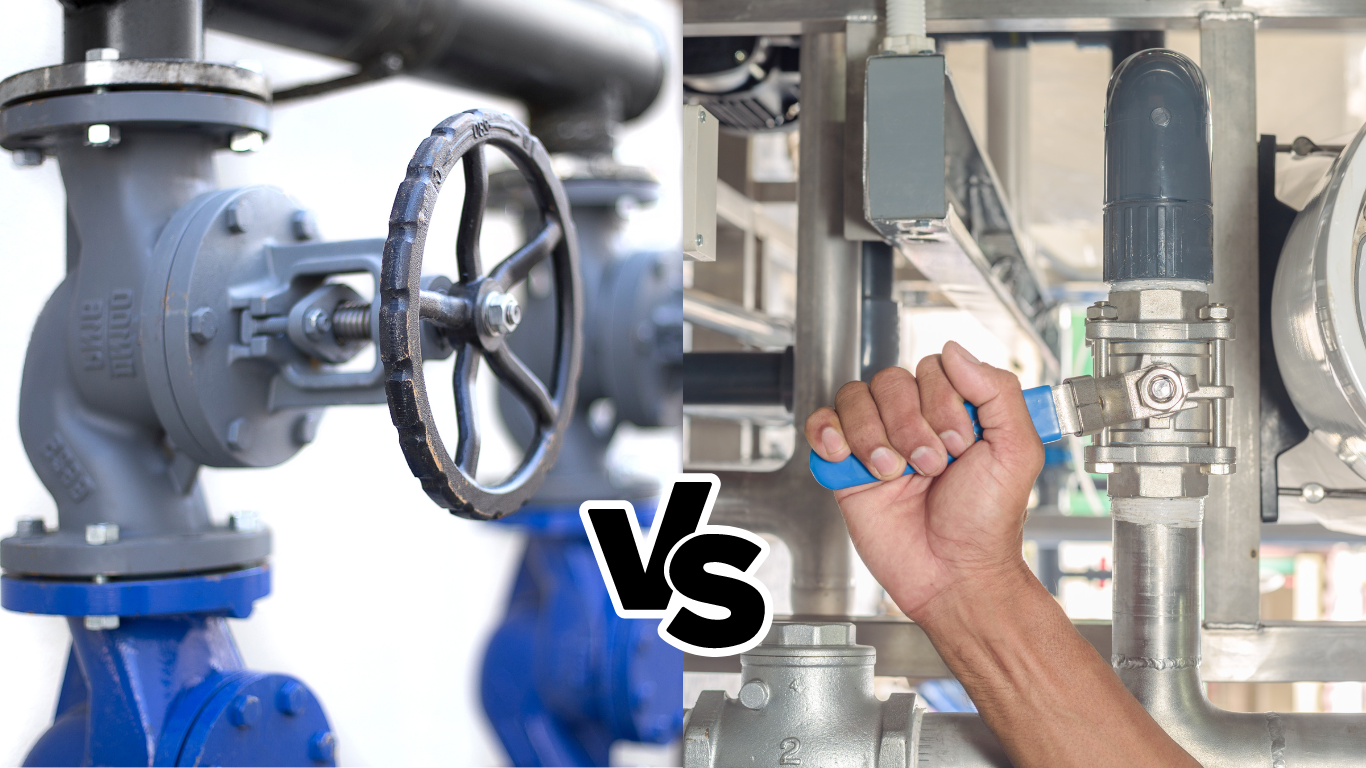

In the intricate world of plumbing and industrial applications, selecting the right valve is crucial. Among the vast range of options available, two types stand out: ball valves and gate valves. While both serve the primary function of controlling flow within a pipeline, they differ significantly in design, operation, and ideal use cases. Let’s delve into the nuances of ball valves and gate valves to understand their strengths, weaknesses, and where each excels.

The Basics

Ball Valves: As the name suggests, these valves feature a spherical disc (the ball) with a hole in the centre. When the valve is open, the hole aligns with the pipeline, allowing fluid to flow. Rotating the handle 90 degrees closes the valve by positioning the solid part of the ball perpendicular to the flow, blocking it completely.

Gate Valves: Gate valves operate by raising or lowering a gate (a flat or wedge-shaped disc) to control the flow of fluids. When fully open, the gate is completely removed from the flow path, offering minimal obstruction. Closing the valve involves lowering the gate into the flow path until it blocks the passage entirely.

Performance Characteristics

1. Flow Control: Ball valves offer superior flow control compared to gate valves, primarily due to their full-bore design. The unobstructed flow path minimises pressure drop and turbulence, making them ideal for applications where precise regulation is necessary.

In contrast, gate valves are prone to flow restriction due to the obstruction caused by the gate within the pipeline. While suitable for on/off applications, they may not provide the fine-tuned control required in certain systems.

2. Durability and Maintenance: Ball valves are renowned for their durability and minimal maintenance requirements. The simple design with fewer moving parts reduces the likelihood of failure, making them suitable for high-pressure and high-temperature environments. Additionally, their ability to seal tightly even after prolonged periods of inactivity enhances their reliability.

Gate valves, while robust, are more susceptible to wear and tear, especially in applications where frequent operation is necessary. The rising stem design makes them prone to corrosion and debris accumulation, requiring periodic maintenance to ensure optimal performance.

3. Application Suitability: The choice between ball valves and gate valves often depends on the specific requirements of the application:

– Ball Valves: These valves excel in applications that demand swift, reliable shut-off and precise flow control. They are commonly used in industries such as oil and gas, chemical processing, and water treatment, where efficiency and safety are paramount.

– Gate Valves: With their ability to provide a tight seal, gate valves are well-suited for applications requiring infrequent operation and where a full flow path is essential, such as in pipelines carrying thick or viscous fluids.

Conclusion

In the debate of ball valves versus gate valves, there is no one-size-fits-all answer. Each type offers distinct advantages and is better suited to specific applications. While ball valves boast superior flow control and durability, gate valves shine in applications where a full bore and tight shut-off are critical.

Ultimately, the selection process should consider factors such as flow requirements, operating conditions, maintenance considerations, and budget constraints. By understanding the strengths and limitations of each valve type, engineers and operators can make informed decisions to ensure optimal performance and safety in their systems.